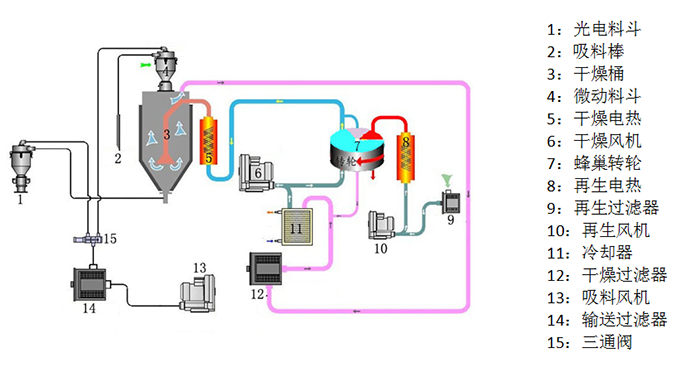

drying and dehumidification part: the hot and humid air from the drying barrel is cooled and blown into the honeycomb runner. The moisture in the air is adsorbed by the runner and then desorbed by the regenerative heating air.

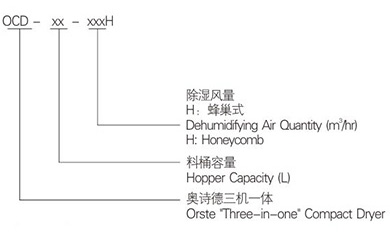

189-4860-6110 / 0769-82020256 Online consultationNaming principle

-----------------------------------------------------------------------------------------------------------------------------

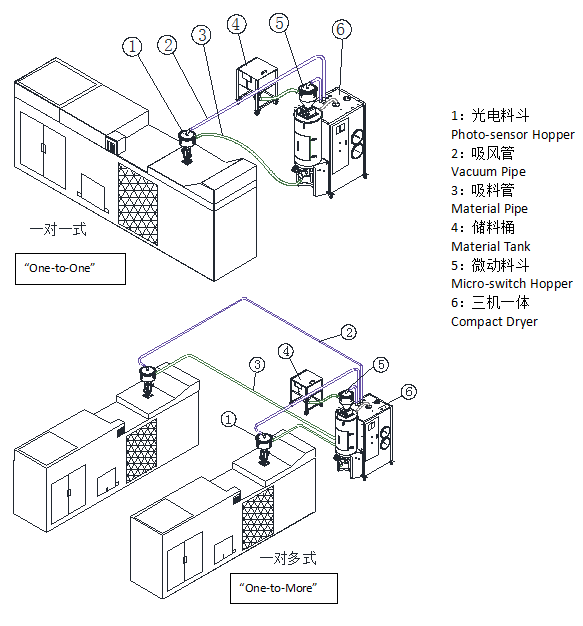

Scope of application

-----------------------------------------------------------------------------------------------------------------------------

working principle

→ drying and dehumidification part: the hot and humid air from the drying barrel is cooled and blown into the honeycomb runner. The moisture in the air is adsorbed by the runner and then desorbed by the regenerative heating air. Two streams of air act on the runner at the same time, and with the rotation of the runner, the water in the air is continuously adsorbed and desorbed by the regenerated air to form a stable low dew point air, which is heated to the drying temperature of the plastic and blown into the drying barrel to form a closed cycle and dry the raw materials.

→ material suction part: material suction is to suck into the dry material bucket from the material storage bucket or other material storage containers. When the magnetic spring switch of the vacuum hopper detects that there is no material, the material suction motor operates to generate vacuum in the vacuum hopper. The raw materials in the material storage bucket are sucked into the vacuum bucket due to the pressure difference of air. When the material suction time is completed, the material suction motor stops running, Raw materials will fall into the dry barrel due to their own weight. The dried raw materials are pumped from the drying barrel to the photoelectric hopper or micro hopper installed in the plastic molding machine.

Product features

1. This series adopts microcomputer P. I. D. temperature control system with accurate temperature control;

2. Nijas brand full molecular sieve honeycomb dehumidification runner imported from Japan is adopted, which has better and more stable dehumidification effect;

3. The large heater is equipped with removable cooler, which is convenient for maintenance and lower return air temperature;

4. High density return air filter to ensure that the honeycomb runner is not polluted by raw material dust;

5. Double layer insulation down blowing stainless steel dryer;

6. The feeding system is equipped with evacuation cut-off valve (quick disassembly type) to ensure that there is no residual material in the pipe;

7. Hot material conveying can be equipped with closed conveying device of hot air circuit, which can effectively avoid raw material pollution and moisture regain;

8. Optional optical grade hopper dryer to adapt to the production of optical grade and food grade products;

9. The transparent window design of the filter can observe the service condition of the filter and clean or replace it regularly;

10. Buckle type sealing plate design makes the later maintenance and repair more convenient;

11. After dehumidification, the air dew point can be as low as - 40 ℃.

technical parameter